UV printer magnetic levitation technology, is another market hot spot following the guide belt, but about the UV printer magnetic levitation technology, is it the same as the magnetic levitation we usually hear of magnetic levitation trains?

We usually hear of magnetic levitation technology because there is no direct mechanical contact, compared with other support technology has the advantages of frictionless, no lubrication, low power consumption, clean, etc.. After a long time of development, magnetic levitation technology is becoming more and more mature, and has been widely used in transportation and industry. At present, the hot spot of magnetic levitation technology research application is still magnetic levitation train and magnetic levitation bearing.

Working principle: linear motor is a new type of motor application is increasingly widespread, magnetic levitation train is driven by linear motor. Magnetic levitation train is a new kind of train. General train, due to friction between the wheels and the iron ghost, limiting the speed of the increase, it can reach a high operating speed of no more than 300km / n. Maglev train is a train with magnetic levitation, so that the train and the rail out of contact, in order to reduce friction and improve speed. The train is pulled by a linear motor, one stage of the linear motor is fixed to the ground, extending to a distance with the rail; the other stage is installed on the train, the primary pass to AC, the train moves along the rail.

The working principle of magnetic levitation technology is to use electromagnetic technology, combined with the position signal of the sensor to generate control current, so that the electromagnet produces electromagnetic force on the levitated object, thus driving the movement of the levitated object. For the field of UV printing, magnetic levitation technology can be applied to common types of UV printers such as UV flatbed printers, UV coil printers, coupled with the Japanese Ricoh G6 high-precision high-speed printheads to improve its printing speed, 30% faster than the current market belt-driven UV printer, the technology is a new breakthrough in the UV printing industry!

The obvious feature of magnetic levitation is to greatly reduce the noise of the equipment scanning printing movement, compared to traditional transmission methods, magnetic levitation can carry a higher speed of movement, but also to solve the problem of wear and tear of parts brought about by the form of belt drive. But a very high-sounding magnetic levitation technology, applied to UV printers on the advantages of how much it can be reflected? I think the magnetic levitation series UV printers can indeed solve the wear and tear problems and carry high speed on its superiority, but if not batch printing or a single print width is not a big scene, this technology still seems a bit chicken.

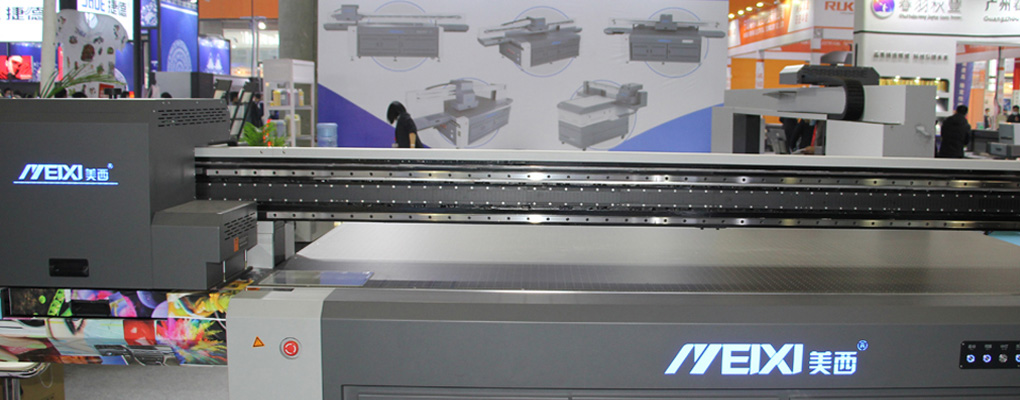

Meixi MX-2513 G6 adopts magnetic levitation motion system instead of belt pulling system, which not only improves the output of the machine, but also solves the accuracy error caused by the belt pulling trolley due to thermal expansion and contraction and belt elasticity. Metal charity will not wear out, durable, reliable and stable, to ensure high-resolution output, linear motor walking more stable, two-way switch more rapid and sensitive.