Industrial UV flatbed machine belongs to a large-format printing out equipment, its nozzle precision, the price is not expensive, on the start-up stores is not a small capital investment, assuming that the usual care, there will be such and such problems. Then, the user in the daily operation to pay attention to what problems?

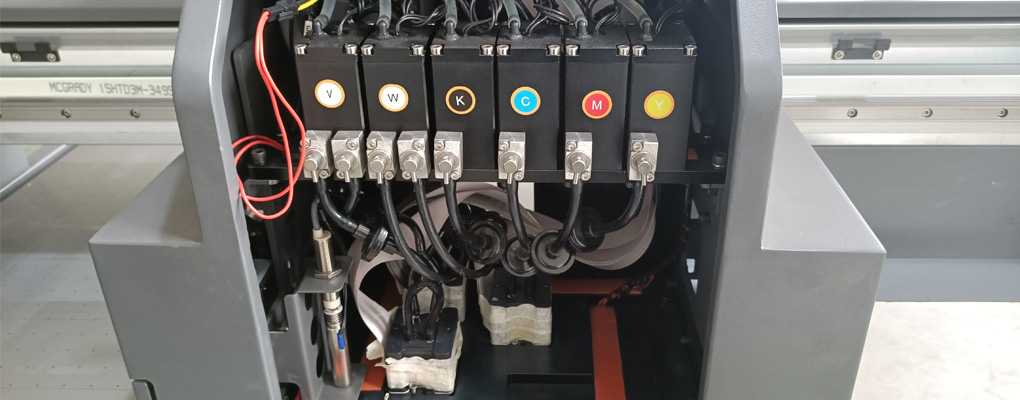

1. To prevent direct contact with the nozzle surface. UV flatbed machine nozzle diameter than the hair is also fine, once the fingers, tools and other stains, dust on the surface, inevitably obstruct the nozzle, the formation of ink break problems. Therefore, the usual assumptions found nozzle appearance is relatively dirty, be sure to wipe with a paper towel that does not fall off, so as not to lint and other debris residue.

2. The correct storage UV flatbed machine nozzle. Usually, we do not recommend storing the nozzle alone, because the external temperature will affect the physical properties of the remaining ink inside the nozzle, such as high temperature will lead to the volatilization of ink solvent, fast solidification, causing nozzle obstruction. Assuming that not timely cleaning, there may be corrosion of internal electronic components, then, the printhead is completely scrapped.

3. The correct shutdown. In order to ensure the normal use of flatbed printers, to prevent inconvenience caused by power failure, be sure to install the transformer in the workplace. Before shutting down, the gear should be turned to OFF, the printhead to return to the position after the blockade of power, after unplugging. Never suddenly block the power supply, which will lead to the nozzle can not return to the ink stack in time and exposed to the air, easy to appear ink withered plugging phenomenon.

UV flatbed machine printing pattern solidification speed is relatively fast, mainly relying on the UV lamp sudden onset of high heat. However, users may encounter the problem of incomplete curing, how does this happen? How to deal with?

1. life has been exhausted. UV lamp also has a certain life, once close to or more than the use of time, the heat intensity of its episodes will be rapidly reduced, can not let the picture a short time completely solidified.

2. Voltage instability. Assuming that the rush to the peak period of electricity, it is easy to present the problem of high and low voltage, such frequent fluctuations in the UV flatbed machine into a normal state, therefore, the user must be installed voltage regulator.

3. Initial start. Just start the equipment, UV lamp output power has not reached a large value, so it is better to clean the nozzle first in the start, so that all parts into working condition before starting to print.

In addition, the whole machine aging, power supply mismatch and other reasons is also the cause of UV flatbed machine spray painting material solidification slow, so the user in the use of the information before the information to check, do a good job of routine maintenance, extend the life of the machine to ensure good printing results.

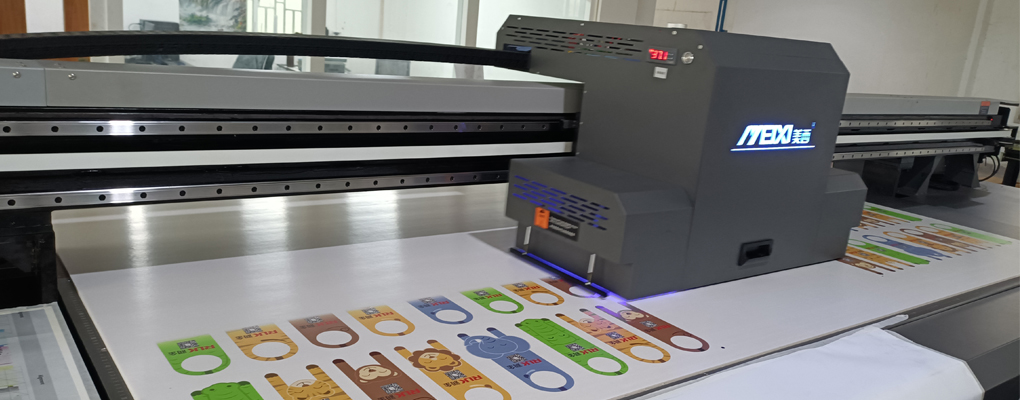

Meixi UV flatbed printer full models using cold light source UV-LED system curing, longer life, more energy efficient and power saving, printing instant drying, to expand the scope of application of the printer material, full models using the head anti-collision configuration, in order to provide you with better printing help at the same time, to ensure the safety of the print nozzle, reduce your use of UV machines on the nozzle loss. printers use environmentally friendly UV curing ink adapted to Ricoh printheads as standard, and are equipped with a secondary cartridge heating function to ensure fast printing while ensuring that the ink does not solidify, thereby reducing the appearance of printing failures.